Even though you may be new to machine embroidery, you have undoubtedly seen embroidery backings on shirts that you have worn in the past. The stabilizer is a piece of fabric that serves as support during the embroidery process. Most of the time is comes behind the stitches, sometimes it stays with embroidery work but it’s removable types are also available. Embroidery machine stabilizers are the heroes that have been saving millions of our creations.

What embroidery stabilizer is made of?

The majority of backings are wet-laid nonwovens, which are composed of haphazard fibers bound together by a binder. Nonwoven backings are strong and stable enough to be used as embroidery machine stabilizers because of their non-directional nature.

It’s important to use nonwovens made for machine embroidery; you may come across online advocates for using odd materials as backings, such as paper towels, coffee filters, and newspapers. During embroidery, these items may break apart, producing an excessive amount of lint in your machine parts and bobbin cases.

Why using stabilizer is so important?

After discovering embroidery stabilizers, you come to know that the benefits of using it are countless. They provide stability and prevent fabric distortion, make your embroidery stays crisp and well-defined. puckering or shifting of the fabric during stitching, resulting in a polished and professional-looking finished product right from your home.

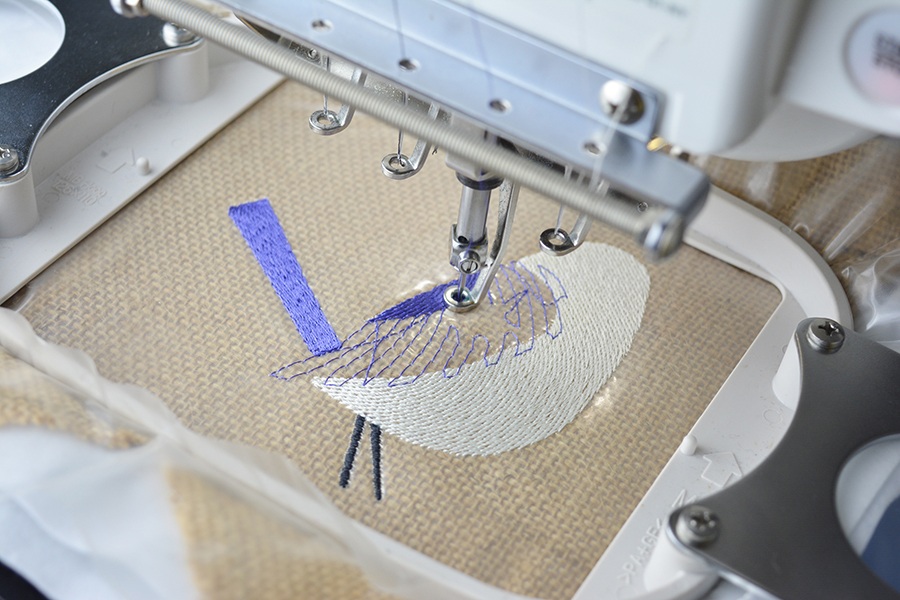

So, using stabilizers is the fundamental part of machine embroidery. Sometimes it is placed on both the back and top sides of the fabric. When working with fabrics that have raised fibers, commercial embroiderers always use a Tear Away or Cut Away backing and apply a layer of wash away stabilizer on top. Home embroiderers these days know they need something to stabilize their fabric. Typically, the machine or the digitization process are to blame, but the actual problematic thing is not using a stabilizer or the right kind of stabilizer. Even though a poorly digitized design is frequently the cause, keep in mind that if proper stabilization is lacking, you will always struggle to achieve high-quality results.

How embroidery machine stabilizers are used?

Here comes the hard part, after understanding their importance. Stabilizers are wet-laid at the back or sometimes even on top of the fabric. Their non-woven nature makes them easier to tear away or cut away. Use of non-woven stabilizers is important for machine embroidery.

It is always better to hoop stabilizer with the fabric. To secure the pieces while hooping, it is useful to apply temporary spray adhesive to the stabilizer and then attach it to the fabric. Don’t forget to check that the stabilizer and fabric are both smooth and flat inside the hoop. Also, do not extra stretch it.

Why there are so many types of embroidery machine stabilizers? When and why, you should use stabilizer?

Stabilizers come in different varieties. Your selection depends on the material you are working with. The right stabilizer choice involves many considerations, including:

- Weight, quality and type of fabric.

- Design density.

- If it can be hooped with the embroidery project or not.

Choosing a stabilizer:

Look for a stabilizer made with non-directional materials, with no grain. You may also want to hold the stabilizer up to the light to make sure of a consistent thickness, with no thin or bald-looking spots! Below are some helpful tips for choosing the right stabilizer for your project:

Determine fabric Type:

Think about the type of fabric you’re embroidering. Is the fabric stable or stretchy? Will it need a stabilizer? As a general rule, tearaway is used on non-stretch fabrics, while cutaway is best for stretchy fabrics like t-shirts and sweatshirts.

Evaluate the Design:

Next, consider the embroidery design you’re going to use. How many stitches does it have? Remember that the more stitches a design has, the heavier the stabilizer needs to be. Also think about the components of the design. For example, are there complicated spots within the design where removing bits of stabilizer might be difficult?

Consider the Purpose:

It’s also important to consider the purpose of the embroidered item. Will you be seeing it from both sides, like lace? Will the embroidery be lying against the skin? Which backing will be the least visible and the most comfortable?

Experiment:

The best way to really become educated about stabilizer is to experiment. Everyone has an opinion on which stabilizers are best, and you need to discover your own preferences according to your needs. Ask embroidery experts around you, what and why they like to use for a certain type of project.

How will the project be embroidered with the right kind of embroidery machine stabilizers? Will it be covered or visible?

The intended outcome is whether the stabilizer will show through the fabric or if the back of the embroidery is visible. Let’s see how it is used with different types of fabric:

Stretchy Fabrics:

The most frequent cause for using a stabilizer is this. If you use stretchy fabrics, stabilizer will keep your embroidery from folding over as you stitch. It is nearly always required when sewing t-shirts. You can also use temporary stabilizer for these purposes. But if you plan to wash your embroidery a lot, you might want to think about leaving it in place for added support.

Semi-sheer fabrics:

Stabilizer can help if you are going to embroidered on a light-colored or semi-sheer fabric and the back of your work will be visible. Even as a thin stabilizer, the additional layer keeps your work from being seen through. A good example is black work, where the white fabric will show through the dark-colored floss. For this, a permanent stabilizer is a wise option.

Lightweight fabrics:

Embroidering on lightweight materials can cause the puckering especially when it comes out of the hoop. The fabric becomes more, well, stable when stabilizer is added. There’s also a less chance of the stitches ripping the fabric.

Loose-weave or knitted fabrics:

Some fabrics, like linen, may be slightly spaced from one another. Because of this, it may be more difficult to stitch smooth lines in embroidery because there are fewer spaces available for passing the needle and thread through. The stabilizer forms an invisible framework on the back of your work that resembles a tight weave. When you’re finished, use permanent stabilizer to prevent the stitches from shifting.

Conclusion:

Embroidery stabilizer is a must have item for every embroidery enthusiast, expert or a beginner. Always test out a stabilizer with your fabric before starting with your main project. Check out this articles and discover all types of stabilizers.

Edible Easter Slime

Mauris congue venenatis nisl ut varius. In posuere sem lorem, eu iaculis ante. Quisque eget turpis

Creative Back To School Ideas

Mauris congue venenatis nisl ut varius. In posuere sem lorem, eu iaculis ante. Quisque eget turpis

Exclusive Content

Be Part of Our Exclusive Community

Sed finibus, sem elementum tincidunt tempor, ipsum nisi ullamcorper magna, vel dignissim eros sapien at sem. Aliquam interdum, ante eget sagittis fermentum, mauris metus luctus sem, at molestie.

Leave A Comment