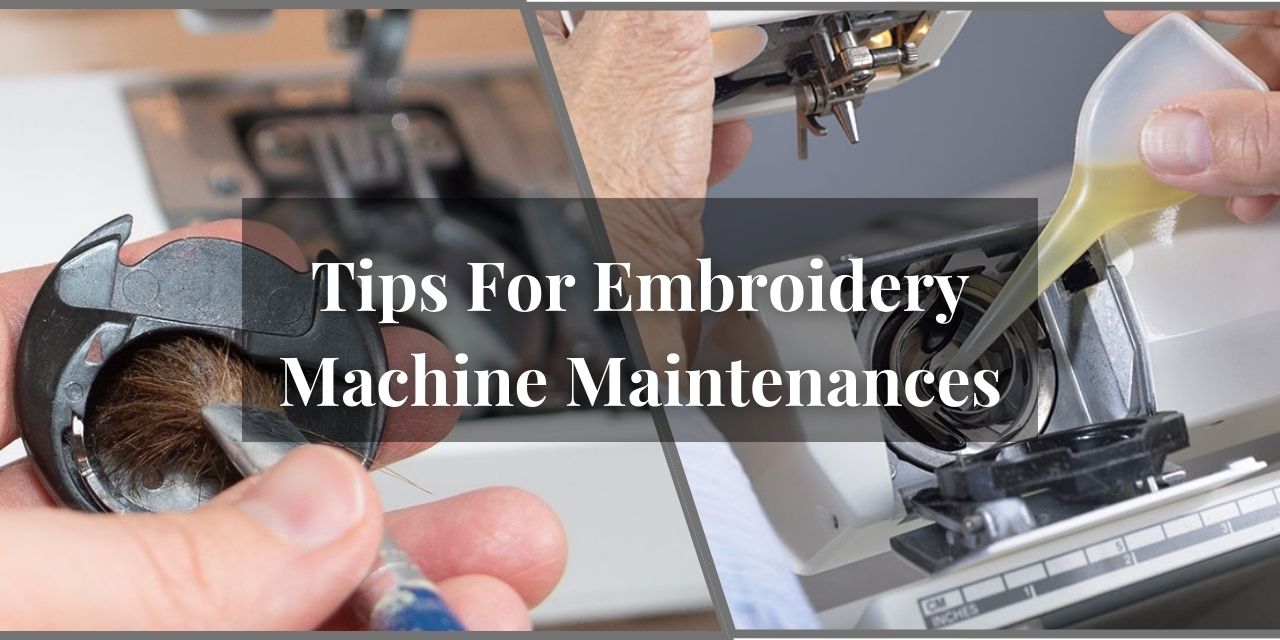

Embroidery machine allows us to bring our imagination into life. To ensure that your machine continues to work at its best and lasts longer, regular machine maintenance is essential. Without proper maintenance and troubleshooting their optimal performance and longevity declines and bring in more destruction. Here are some tips that I have gathered from my experiences and observation around, they help you to not only maintain but also troubleshoot your machine:

Cleaning (degreasing):

Once you open your machine for maintenance, degrease it with mild detergent. Use dish soap mixed in water, dip cloth or a good quality brush. Dust of every thing and then remove the old oil mixed in lint and dust with cleaner. Don’t use harsh chemical bleaches or detergents as it might affects the performance of gears and race. Once everything is cleaned and sparkling, ensure that all parts are dry so that nothing corrodes. Store your machine in dry area all the time.

Lubrication (Oiling):

Lubrication helps keep the moving parts running smoothly. This is the most important step in machine maintenance. Be sure to use the recommended machine oil, it is mostly light weighted and not heavily greasy, beeswax is commonly used. Do not use baby oil, it is not good for machine. Apply it to the designated points, as it comes on the instructions the manual guide.

I’d recommend regular oiling as it prevents friction, helps with the smooth stitching and increases the lifespan of your machine. Follow the instructions in user manual if have any doubts for oiling your machine.

Apply oil sparingly and wipe away any excess, embroidery machines are not meant to be drench in the oil, they require very less. The general rule is that you oil it once a week, or after an estimated sewing time if 40 to 50 hours. The least you are supposed to do it is at least thrice a month. It basically depends on your use and the type of machine you are using, just don’t let it rust.

Parts that needs Oiling:

Before you read this part of the article, go through the instructional manual of your embroidery machine. Some of them says that you are not supposed to oil them at home. Some recommend it after every use of 10 hours. It varies from manufacturer to manufacture. Some Embroidery or sewing machines are self lubricating even. Now let’s look at what are the common parts that need oiling in most of the machines: shuttle and bobbin hook, gears, race and housing.

Needle Care:

The needle is one of the must have component of your embroidery machine. Replace the needle regularly,using a becomes dull or bent needle can also ruin your machines internal performance. Remember to choose the correct needle size and type for the fabric you’re working with.

Replace needles after every 8-10 hours(estimated time) of embroidery or when they become dull, bent, or damaged. Using worn needles can cause thread breaks, extra lints, skipped stitches, excessive stitch in one place, or fabric damage.

Thread and it’s tension:

Proper thread tension is important for achieving high-quality embroidery. Regularly check the thread tension and adjust it accordingly. Loose or tight stitches can affect the appearance and durability of your embroidery. Experiment with different tension settings to find what works best for different fabrics and designs.

Also ensure that the upper and bobbin thread tensions are balanced and suitable for the fabric and thread being used. Adjust tension settings as needed to prevent issues like thread looping, puckering, or breakage.

Bobbin Winding:

Ensure that you wind the bobbin correctly for optimal performance. An evenly filled and smoothly wound bobbin prevents thread jams and ensures consistent stitching. Follow the instructions in your machine’s manual to ensure proper bobbin winding technique.

Storage:

When your machine is not in use, store it properly. Cover your machine to protect it from collecting dust. A dust cover or a clean cloth big enough to cover the machine can do the job. Store your machine in a dry and clean area to avoid any potential damage. Avoid exposing it to extreme temperatures or humidity.

Replace Worn Parts:

Keep an eye out for any worn or damaged parts, such as the bobbin case, needle plate, or presser foot. Replace them as necessary to maintain smooth operation.

Troubleshooting:

If you encounter issues with your machine, here are a few troubleshooting steps you can try:

- Check the threading: Make sure the machine is threaded correctly, both in the upper and bobbin threads.

- Clean the bobbin area: Remove the bobbin case and clean out any lint or tangled threads that may be causing issues.

- Re-thread the machine: Sometimes, re-threading the machine can help resolve tension or stitching problems.

- Check the needle: Ensure that the needle is properly inserted and not bent or damaged.

- Consult the manual: If the issue persists, refer to the user manual for specific troubleshooting steps or contact the owner or store dealer for assistance.

Conclusion:

Following these easy and effective maintenance and troubleshooting tips, you can keep your embroidery machine in excellent shape and enjoy smooth and efficient embroidery projects. Remember the best guide to take care of your machine is its own use manual.

Edible Easter Slime

Mauris congue venenatis nisl ut varius. In posuere sem lorem, eu iaculis ante. Quisque eget turpis

Creative Back To School Ideas

Mauris congue venenatis nisl ut varius. In posuere sem lorem, eu iaculis ante. Quisque eget turpis

Exclusive Content

Be Part of Our Exclusive Community

Sed finibus, sem elementum tincidunt tempor, ipsum nisi ullamcorper magna, vel dignissim eros sapien at sem. Aliquam interdum, ante eget sagittis fermentum, mauris metus luctus sem, at molestie.

Leave A Comment